Climate Change

Our Concept and Policy of Climate Change

As climate change intensifies, with natural disasters becoming more frequent, the role and responsibility of companies in realizing a “decarbonized society” are growing increasingly crucial.

SII’s environmental policy emphasizes our commitment to combatting climate change: “Being acutely aware of the part we have to play in mitigating climate change, we are working hard to reduce greenhouse gas emissions.”

To achieve this, we focus on three key areas: energy-saving activities for both CO2 and non-CO2 greenhouse gases, the introduction of renewable energy, and reducing emissions across the value chain.

In terms of products and services, we prioritize the development of energy-efficient products, considering power consumption as a critical factor within our Green Product System.

In our energy-saving initiatives, we promote the efficient operation and management of facilities, the upgrading to high-efficiency equipment, and the implementation of everyday energy-saving practices. We believe these efforts must be sustained over time.

Given the diverse types and methods of renewable energy, we recognize the importance of selecting the most suitable approach based on the specific location and characteristics of each unit.

Long-Term Targets

SII is dedicated to achieving a decarbonized society in line with the long-term greenhouse gas emissions reduction targets set by our parent company, Seiko Group Corporation.

[Seiko Group’s Greenhouse Gas Emission Reduction Targets]

Fiscal Year 2030

Scope 1 & 2:42% reduction compared to the FY2022 level.

Scope 3:25% reduction compared to the FY2022 level, targeting categories 1 and 11.

Fiscal year 2050

Aiming for net zero.

In April 2024, we obtained SBT certification from the Science Based Targets initiative (SBTi) for our FY2030 targets, as they align with the 1.5°C pathway outlined in the Paris Agreement.

FY2023 Summary

In FY2023, we advanced our energy-saving initiatives, focusing primarily on upgrading air-conditioning systems to high-efficiency models and switching to LED lighting fixtures. Regarding renewable energy, we reviewed power contracts and other measures, aiming to convert 100% of the electricity used at our manufacturing sites in Japan to renewable energy by FY2024. Additionally, we reassessed the greenhouse gas (GHG) emissions of tenant-occupied areas by proportionally dividing the space to ensure accurate measurement. As a result of these efforts, GHG emissions at our domestic sites were reduced by approximately 25% compared to the previous fiscal year.

Although the scope of GHG emissions at international sites was expanded, reduced production led to a 0.4% decrease compared to the previous year.

To reduce GHG emissions within the value chain, we are focusing on emissions generated during product transportation. We are promoting a modal shift, such as transitioning some product shipments from air to sea transport.

We also continued to disclose information based on TCFD recommendations as part of the Seiko Group.

As a new initiative, we obtained third-party verification of our GHG emissions and water withdrawal as a Seiko Group company.

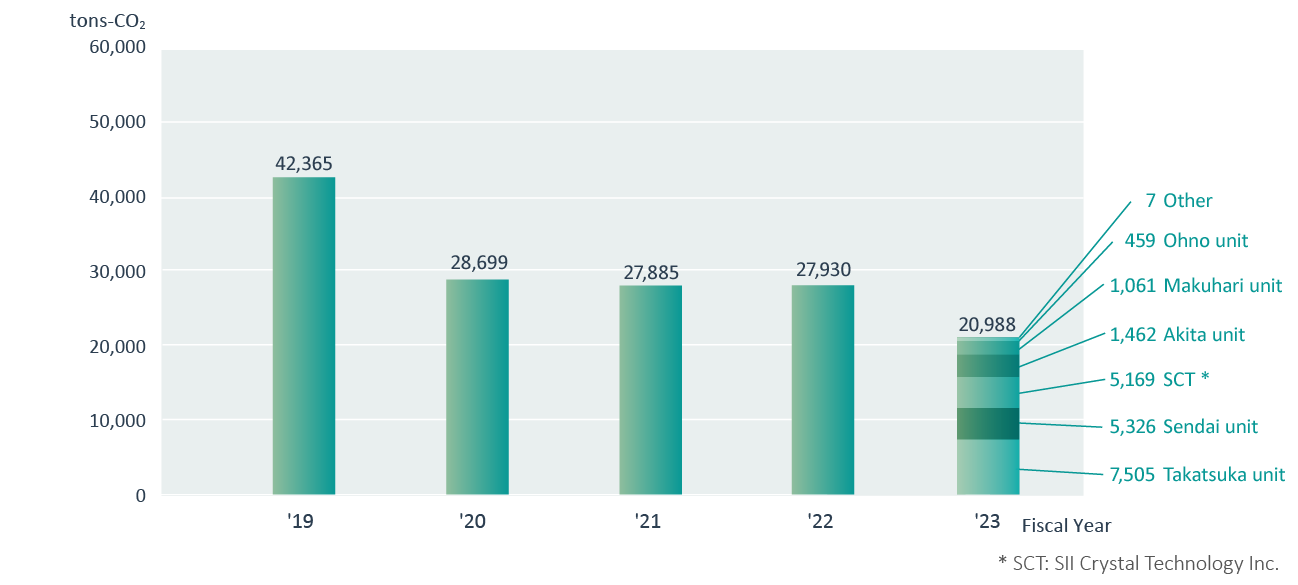

Greenhouse Gas Emissions (Japan Sites)(t-CO2)

| GHG Emissions (Japan Sites): 20,988 tーCO2 |

6,942 tonsーCO2 decrease, or -24.9% from FY 2022 |

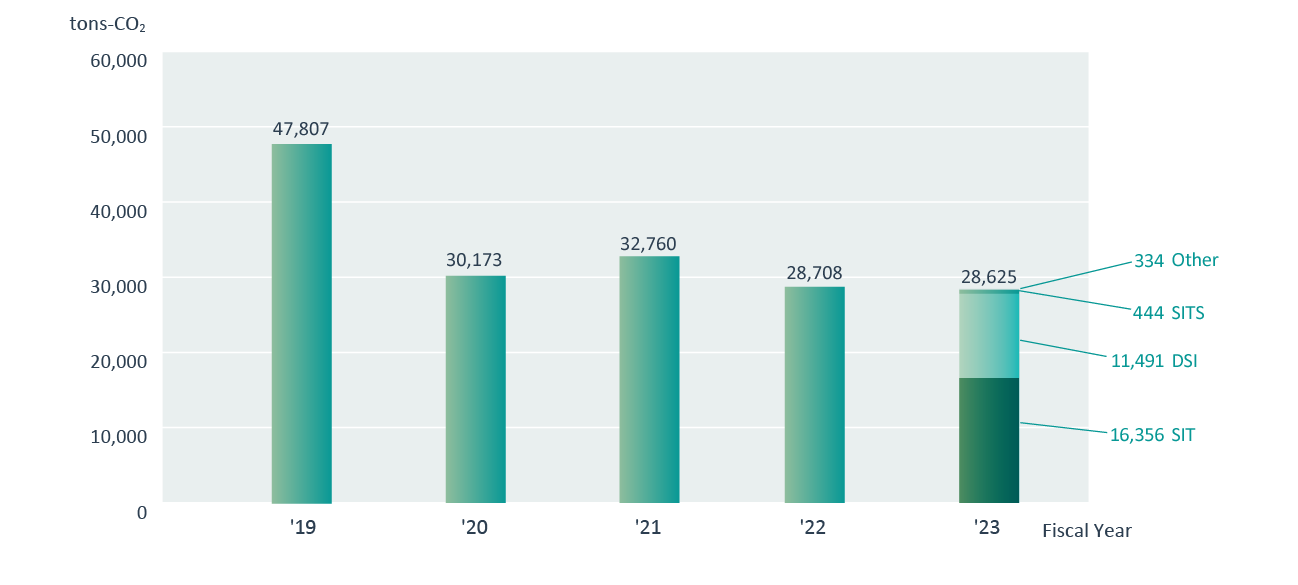

Greenhouse Gas Emissions (Overseas Sites)(t-CO2)

| GHG Emissions (Overseas Sites): 28,591 tーCO2 |

118 tonsーCO2 decrease, or -0.4% from FY 2022 |

- Overseas bases

- SIT: Seiko Instruments (Thailand) Ltd.

- DSI: Dalian Seiko Instruments Inc.

- SITS: Seiko Instruments Technology (Shanghai) Inc.

■Greenhouse Gas Emissions by Scope [Sites in Japan]

| FY 2019 | FY 2020 | FY 2021 | FY 2022 | FY 2023 | |

|---|---|---|---|---|---|

| Scope1 | 3,584 | 3,172 | 3,409 | 3,327 | 3,276 |

| Scope2 | 38,781 | 25,527 | 24,476 | 24,603 | 17,712 |

| Total | 42,365 | 28,699 | 27,885 | 27,930 | 20,988 |

*There are some items that do not add up to the total due to fractional processing.

Scope 1: Direct emissions from owned or controlled sources, such as fuel combustion

Scope 2: Indirect emissions (market-based) from the use of electricity supplied by other companies

■ Calculation Scope:

Includes all SII Group companies, both in Japan and internationally.

Covers greenhouse gases beyond CO2.

No GHG emissions from biological sources.

■ Emission Factors:

- Electricity: Calculated using the IEA's Emissions Factors dataset.

- Fuel: Calculated using the List of Calculation Methods and Emission Coefficients from the Calculation, Reporting, and Publication System, in accordance with the Law Concerning the Promotion of Measures to Cope with Global Warming.

- Greenhouse gases other than CO2: Calculated using the List of Calculation Methods and Emission Coefficients from the Calculation, Reporting, and Publication System, in accordance with the Law Concerning the Promotion of Measures to Cope with Global Warming.

■Greenhouse Gas Emissions by Scope [Sites outside Japan]

| FY 2018 | FY 2019 | FY 2020 | FY 2022 | FY 2023 | |

|---|---|---|---|---|---|

| Scope1 | 473 | 464 | 757 | 728 | 3,562 |

| Scope2 | 47,334 | 29,708 | 32,003 | 27,980 | 25,029 |

| Total | 47,807 | 30,173 | 32,760 | 28,708 | 28,591 |

*There are some items that do not add up to the total due to fractional processing.

Scope 1: Direct emissions from owned or controlled sources, such as fuel combustion

Scope 2: Indirect emissions (market-based) from the use of electricity supplied by other companies

■ Calculation Scope:

Includes all SII Group companies, both in Japan and internationally.

Covers greenhouse gases beyond CO2.

No GHG emissions from biological sources.

■ Emission Factors:

- Electricity: Calculated using the Emission Factor by Electric Utility in the Law Concerning the Promotion of Measures to Cope with Global Warming.

- Fuel: Calculated using the List of Calculation Methods and Emission Coefficients from the Calculation, Reporting, and Publication System, in accordance with the Law Concerning the Promotion of Measures to Cope with Global Warming.

- Greenhouse gases other than CO2: Calculated using the List of Calculation Methods and Emission Coefficients from the Calculation, Reporting, and Publication System, in accordance with the Law Concerning the Promotion of Measures to Cope with Global Warming.

■Greenhouse Gas Emissions by Scope [Total of sites in and outside Japan]

| FY 2019 | FY 2020 | FY 2021 | FY 2022 | FY 2023 | |

|---|---|---|---|---|---|

| Scope1 | 4,057 | 3,636 | 4,166 | 4,055 | 6,839 |

| Scope2 | 86,115 | 55,235 | 56,479 | 52,583 | 42,741 |

| Total | 90,172 | 58,872 | 60,645 | 56,638 | 49,579 |

*There are some items that do not add up to the total due to fractional processing.

■ Greenhouse Gas Emissions by Scope3

| Category | Item | GHG emissions (t-CO2) |

% |

|---|---|---|---|

| Category 1 | Products and services purchased | 82,131 | 61.7% |

| Category 2 | Capital goods | 10,746 | 8.1% |

| Category 3 | Fuel and energy-related activities not included in Scope 1, 2 |

7,573 | 5.7% |

| Category 4 | Transportation and distribution (upstream) | 6,154 | 4.6% |

| Category 5 | Waste from business activities | 1,499 | 1.1% |

| Category 6 | Business travel | 1,375 | 1.0% |

| Category 7 | Employee commuting | 2,184 | 1.6% |

| Category 8 | Leased assets (upstream) | 122 | 0.1% |

| Category 9 | Transportation and distribution (downstream) | 39 | 0.0% |

| Category 10 | Processing of sold products | 147 | 0.1% |

| Category 11 | Use of sold products | 20,874 | 15.7% |

| Category 12 | Disposal of sold products | 324 | 0.2% |

| Category 13 | Leased assets (downstream) | - | - |

| Category 14 | Franchises | - | - |

| Category 15 | Investments | - | - |

| total | 133,168 | 100.0% |

■ Promotion of LED Lighting

SII is systematically promoting the use of LED lighting across its Japanese and international sites.

In FY2023, this initiative continued to be implemented at each of our sites.

■ Facility Improvement and Renewal

In FY2023, we continued our efforts to enhance and renew facilities as part of our ongoing energy conservation initiatives.

At Dalian Seiko Instruments Inc. (DSI) in China, we focused on improving the cooling water system.

Conventional cooling water systems consume a fixed amount of electricity regardless of the load, including fluctuations in air temperature. By enabling pump operation to be controlled in response to load variations, we have successfully reduced electricity consumption by approximately 50%. In the future, we will explore opportunities to recover and reuse heat from the cooling water system during the winter months.

SII Crystal Technology Inc. is advancing with the renewal of air conditioning equipment as part of a five-year plan. In FY2023, the third year of the plan, five new units were installed.

Examples for FY2022

■ Introduction and expansion of renewable energy

Solar power is continuously being introduced at Seiko Instruments (Thailand) Ltd. They installed solar panels on the roof of the structure at the Gateway factory in 2022 and started operation of a solar power system from February 2023. Seiko Instruments (Thailand) Ltd. has the largest amount of greenhouse gas emissions in the SII Group. SII will introduce solar power as planned as it works to reduce greenhouse gas emissions.

■ Seiko Instruments (Thailand) Ltd. is certified for Green Industry Level 4

Seiko Instruments (Thailand) Ltd.’s two factories received Level 4 certification from the Green Industry Project promoted by the Ministry of Industry of Thailand. The Green Industry Project is intended to increase awareness in the industrial industry of environmental and societal problems and develop a sustainable industry. Certification is divided into five levels from Level 1 through Level 5 based on the degree of contribution to the environment. Seiko Instruments (Thailand) Ltd. was recognized for its continuous environmental activities based on the environmental management system and acquired Level 3 (Green System) status in 2018. The next step, Level 4, requires a corporate culture in which all employees working at the plant act while bearing responsibility for the environment and society. After acquiring Level 3, all employees at Seiko Instruments (Thailand) Ltd. engaged in various environmental activities to reach Level 4 (Green Culture). Examiners said, “all employees are highly aware of the environment and put this awareness into practice”.

■ Promotion of conversion to LEDs

SII promotes the conversion of lighting to LEDs systematically at each plant.

SII Crystal Technology Inc. promoted the conversion of ceiling lights to LEDs through a four-year plan in 2019. The plan was completed in FY 2022, and 1,150 units were exchanged in four years.

Examples for FY2021

■ Introduction of Renewable Energy

The Sendai Unit has introduced renewable energy and started its operation in March 2022. Under a power purchase agreement (PPA service) with Fuyo General Lease Co., Ltd. a solar power generation system of approximately 760 kW has been installed on the roof of the Sendai Unit plant, and the Sendai Unit is using the green power generated by the solar power. Sendai Unit manufactures micro batteries, small magnets, Superior Performance Co-Ni Alloy Products (SPRON), etc., and has the highest CO2 emissions of any of SII's sites in Japan. SII will continue to accelerate its efforts toward decarbonization by systematically introducing renewable energy.

At the Navanakorn Factory of Seiko Instruments (Thailand) Ltd. (SIT), solar panels were installed on the factory premises, and the solar power generation system began operating in June 2021. Subsequently, more solar panels were added on the same premises, and a total of 1.7 MWp of electricity has been generated since October 2021. SIT is the operating company with the largest amount of CO2 emissions in the SII Group. We will continue to systematically introduce solar power generation to reduce CO2 emissions.

■ Promotion of LED Lighting

SII's business sites are systematically promoting the use of LED lighting.

SII Crystal Technology Inc. has been promoting the use of LEDs in a four-year plan starting in 2019. In FY 2021, 292 fluorescent lamps were replaced.

■ Facility Renewal

Seiko Instruments (Thailand) Ltd (SIT). is developing the Energy Conservation and Improvement Project. As part of this project, SIT is updating its facilities and improving operations in FY 2021. The Navanakorn Factory upgraded the air conditioning units in the office area, reducing annual electricity consumption by approximately 55,000 kWh. The Gateway Factory has reduced its annual electricity consumption by approximately 360,000 kWh by changing the fin coils used in the chiller heat exchanger.

We will continue to promote energy-saving activities along with the use of renewable energy

Examples for FY2020

Introduction of Renewable Energy

At the Navanakorn Factory of Seiko Instruments (Thailand) Ltd. (SIT), solar panels were installed on the factory premises, and the solar power generation system began operating in June 2021. The scale of this system is 0.7 MWp. SIT is the operating company with the largest amount of CO2 emissions in the SII Group. We will continue to systematically introduce solar power generation to reduce CO2 emissions.

Participation in the Energy Efficiency Improvement Project

The Gateway factory of SIT participated in the Energy Efficiency Project sponsored by the Department of Alternative Energy Development and Efficiency (the efficiency bureau), Thailand, which asks companies to participate in a survey to determine the energy efficiency standards for factories. The Gateway factory cooperated in field surveys such as the chiller power usage survey and the efficiency bureau presented them with a certificate of appreciation for their participation in the project.